Forging Excellence: The World of Seamless Rolled Rings

Seamless Rolled Ring

Seamless Rolled rings are fundamental parts that play a critical part in a large number of industries, from aviation and automotive to huge machinery. These accuracy-made rings are a demonstration of design excellence, offering excellent strength, solidness, and flexibility. In the realm of manufacturing, Seamless Rolled Rings are the unrecognized yet truly great heroes that empower the consistent operation of endless machines, guaranteeing unwavering quality and execution in the most demanding marketplace.

The most common way of manufacturing Seamless Rolled Rings is a mix of craftsmanship and science, where raw substances are carefully produced, formed, and idealized to make a seamless and strong Ring Rolling with the highest quality mechanical properties. These rings come in different sizes, from little and intricate to huge and forcing, serving various capabilities and applications all around the enterprises.

On this page, we will set out into the broad ways of Seamless Rolled Rings, exploring their types, structure, production process, applications, and the fundamental job they play in various areas.

Whether you’re a tech-savvy engineering guy trying to comprehend the complexities of these rings or an expert in a field where their utilization is analytic, this investigation will reveal insight into the wonderful space of Seamless Rolled Rings.

Process of Seamless Rolled Rings

The Seamless Rolled Rings process is a particular metalworking process used to areas of strength to make roll rings for different modern applications. Here is a worked-on three-step process for creating seamless rolled rings:

- The ring roll process starts with the idler roll applying strain to the preform against the drive roll.

- Ring breadths are expanded as the ceaseless tension decreases the wall thickness.

- The process goes on until the desired size is accomplished.

Materials Used

-

Alloy Steel

-

Carbon Steel

-

Stainless Steel

-

Non-Ferrous Metals

Weight Range/Dimensions

Seamless Rolled Rings can go in size from a couple of inches to sizes 6.5 feet in outside dimension, 1 feet in level and 1100 pound in weight. The state of Seamless Rolled Rings can be designed to be flatter, similar to a washer, or to have high walls like a hollow cylinder.

Products Under Seamless Rolled Rings

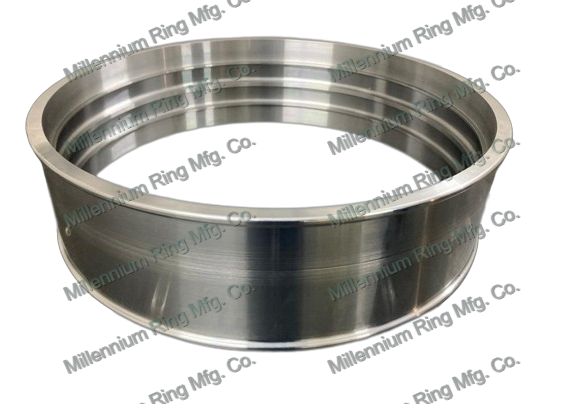

Hot Rolled Ring

Hot Rolled Ring

Hot Rolled Ring, a class of Seamless Rolled Rings, offers a flexible and vigorous answer for a great many modern uses. These accurately designed parts are known for their excellent mechanical properties and seamless development. Whether you want a little and many-intricate ring or a huge and forcing one, Hot Rolled Rings gives the strength, sturdiness, and consistency required as per the environmental behavior.

Key Benefits

-

Seamless Development

Uses seamless manufacturing process, bringing about a deformity-free and uniform design.

-

Flexibility

Come in different sizes to meet prerequisites like industrial scenarios like aviation, auto, & energy.

-

Accuracy Designing

Fulfills strict quality guidelines and is liberated not compromising the performance level.

-

Remarkable Strength

The superior mechanical properties, like high elasticity, endure loads under extreme circumstances.

-

Material Assortment

Created from carbon steel, combination steel, and hardened steel, meets a vast range of enterprises.

Applications

-

Aviation

Used in airplane motors, landing gear, & underlying parts, under strength/unwavering quality.

-

Automotive

Used in drivetrain parts, suspension frameworks, and power transmission, adding security.

-

Energy and Power Age

Used in turbines, generators, and gearboxes, supporting effective and seamless functions.

-

Large equipment

Develops large equipment viz earthmovers, tractors, cranes, & improves heap bearing loads.

-

Oil and Gas

Used in penetrating hardware, siphons, and pipelines, guaranteeing the task's dependability.

-

Course and Pinion wheels

Used to make sturdy and superior execution direction and pinion wheels for different modern gear.

Hot Rolled Ring is an irreplaceable part of various industrial set-ups, where their seamless development, extraordinary strength, and versatility add to the achievement and productivity of different applications. Whether it’s for upgrading the exhibition of an automobile or guaranteeing the unwavering quality of power generation, these rings are designed to satisfy the needs of current industrial aspects.

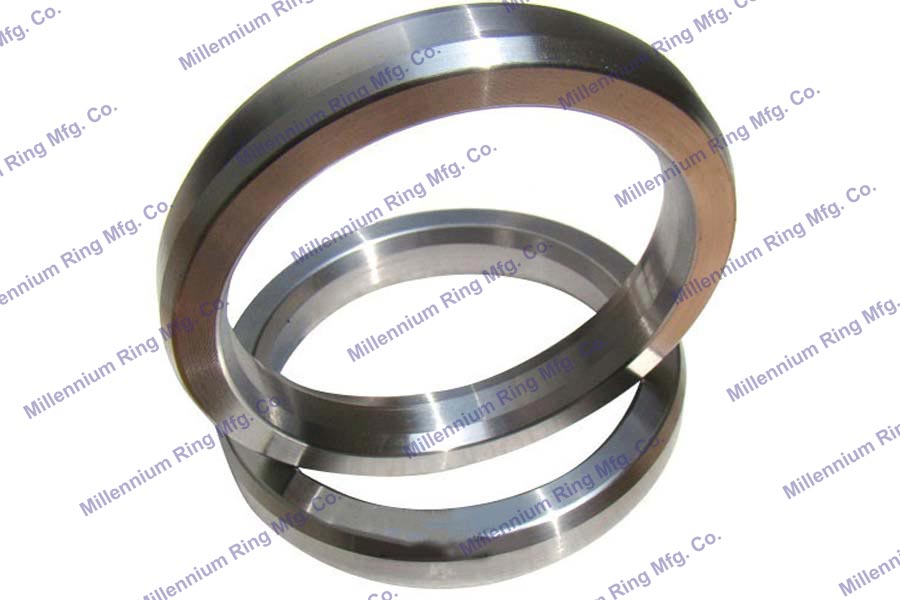

Transmission Gear Rings

Transmission Gear Ring

Key Benefits

-

Seamless Development:

It guarantees a uniform construction and upgrades solidarity, sturdiness, and unwavering quality.

-

Precise Machinery

Ensure a tight fit with other transmission parts and smooth and productive activity of the gear system.

-

Exceptional Sturdiness

The top-notch materials make them tough, equipped for enduring conditions in transmissions.

-

Ideal Power Transfer

Intended for accurate power transfer, improving general effectiveness of the transmission system.

-

High Burden Bearing Capacity

Can endure high loads and stresses on transmissions, guaranteeing long-term reliability.

-

Heat Treatment

Improves the material's solidarity and hardness, guaranteeing rigorous endurance transmission applications.

Applications

-

Programmed Transmissions:

Tracked down in programmed transmission systems to work without a hitch and effectively.

-

Manual Transmissions

Adheres to gear commitment and power movement, guaranteeing precise control for the driver.

-

Differentials

Empowering of circulation of force between wheels to keep up with foothold and steadiness.

-

Heav Vehicles

In bigger/heavier vehicles, transmission gear rings are fundamental for solid power movement.

-

Rough Terrain Vehicles

Benefits strength & unwavering quality of transmission gear rings in testing under liable conditions.

-

Agricultural Tools

Transmissions of tools, where effectiveness and reliability are useful for farming works.

Transmission Gear Ring is truly a great hero of the auto industry world, discreetly empowering seamless rolled, proficient power dissemination, and ideal execution inside different vehicles and mechanical systems. Their seamless construction, accurate engineered work, and remarkable durability make them a vital part of the realm of transmissions.

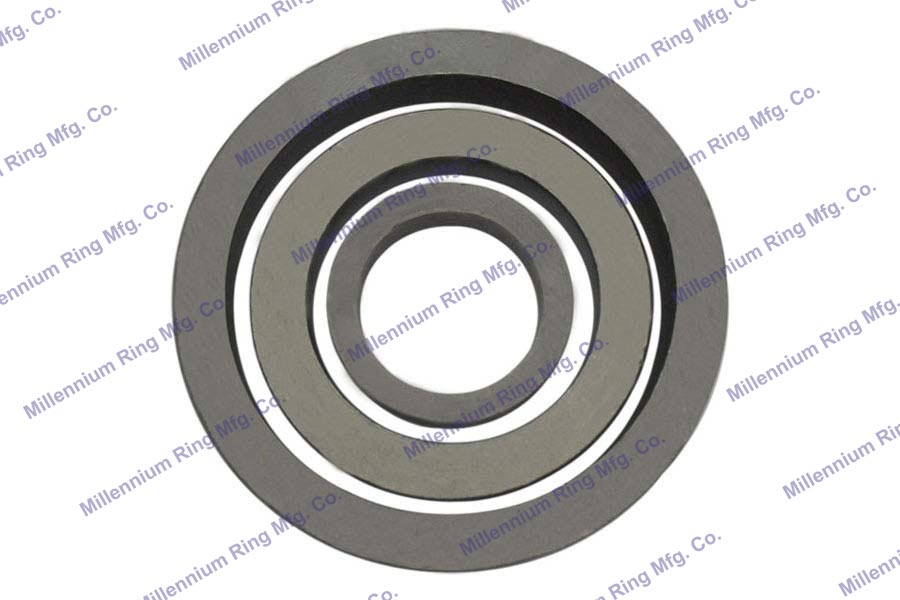

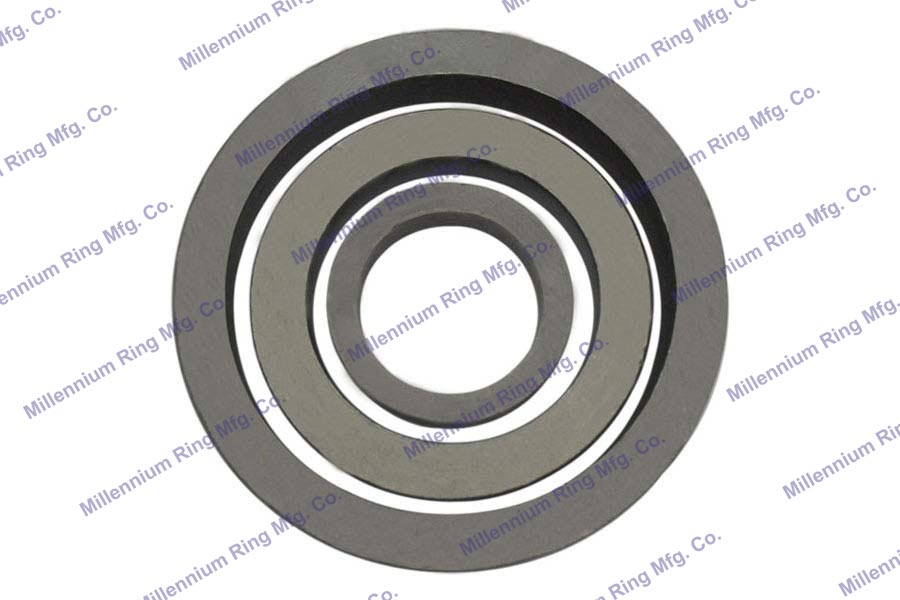

Slewing Ring

Slewing Ring

Slewing Ring, a sort of Seamless Rolled Rings, are profoundly designed parts that assume a significant part in an extensive variety of hardware and gear. These rings are described by their capacity to help hub, outspread, and second loads, making them fundamental for applications requiring smooth, 360-degree rotational development. Slewing rings are planned in light of accuracy and solidness, guaranteeing the dependable and productive operation of equipment across different industries.

Key Benefits

-

360-Degree Rotation

Designed for round-trip rotational development, to easily turn toward any path.

-

Seamless Development

Have a uniform & deformity-free design, upgrading the general strength & unwavering quality.

-

High Burden Bearing Capacity

Help axial, spiral, and second loads, applied for high load-bearing capacity.

-

Corrosion Resistance

Treated against corrosive coatings/materials, guarantees lifespan operating in risky conditions.

-

Precise Machining

Shows exact determinations, to work seamlessly, advancing smooth & proficient development.

-

Durable Materials

Top-notch materials, applicable for guaranteeing solidness and long-term performance.

Applications

-

Construction Hardware

Parts in cranes, excavators, and other weighty equipment, and bring smooth development.

-

Wind Turbines

Empowers the rotation of turbine cutting edges to effectively catch wind energy.

-

Material Taking Care of Gear

Transports, loaders, and stackers use slewing rings to turn and move materials effortlessly.

-

Airborne Work Performance

Blast lifts and flying stages depend on slewing rings for exact situating and activity at heights.

-

Solar Global Tracking System

Use rings to follow the sun's movement over the day, & enhance energy collection.

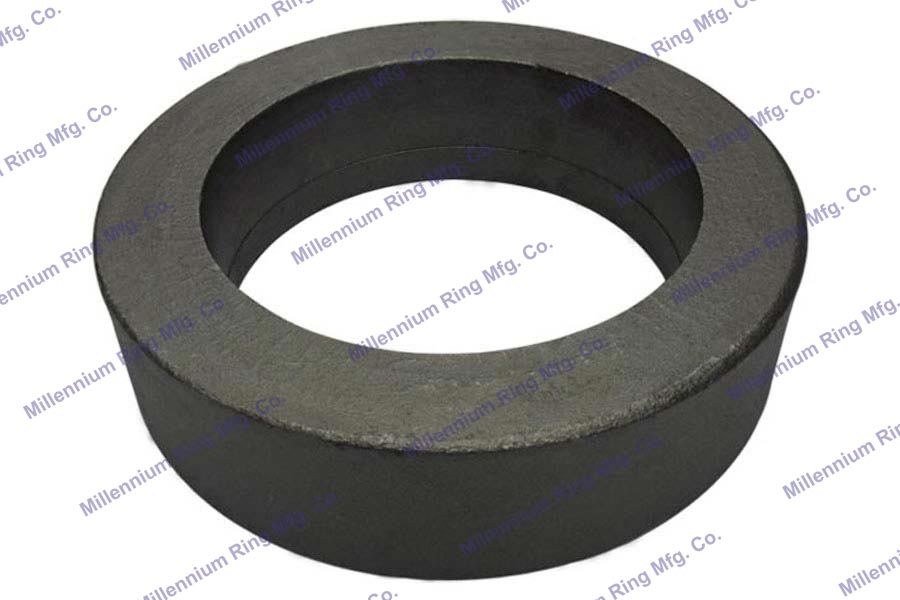

Ring Gear

Ring Gear

Ring Gear, a particular class of Seamless Rolled Rings, are fundamental parts utilized in an extensive variety of industrial hardware and gear. These accurately designed gears are known for their solidness, strength, and exact tooth profile. Ring gears are intended to move rotational movement and power productively, making them fundamental in different mechanical systems.

Key Benefits

-

Seamless Development

Guarantees an imperfection free, uniform construction upgrading solidarity & toughness.

-

Precise Tooth Profile

Works smooth and proficient power transmission under configuration loads rubbing and wear.

-

High Load Capacity

Designed to endure high leads, making them reasonable for large equipment and hardware.

-

Material Flexibility

Made from amalgam steel, carbon steel, and tempered steel, as per the requirement.

-

Size Variability

Comes in lot sizes, and obliges uses, from little mechanical assemblies to huge hardware.

Applications

-

Automotive

Differential gatherings, and starter engines, to smooth stuff commitment and power move.

-

Wind Turbines

Interpretation of wind energy into electrical power by turning the turbine cutting edges.

-

Marine Applications

Used in marine drive frameworks, adds to the development of boat motors and propellers.

-

Agricultural Apparatus

Used to work vehicles, and consolidated reapers, to help effective operation in farming.

Ring Gear is an essential part of mechanical frameworks where exact power transmission, toughness, and dependability are central. Their consistent development, accurate design, and capacity to endure weighty burdens make them irreplaceable pieces of different ventures and hardware.

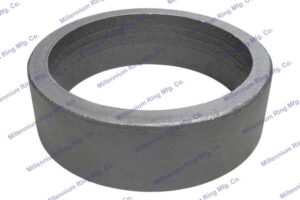

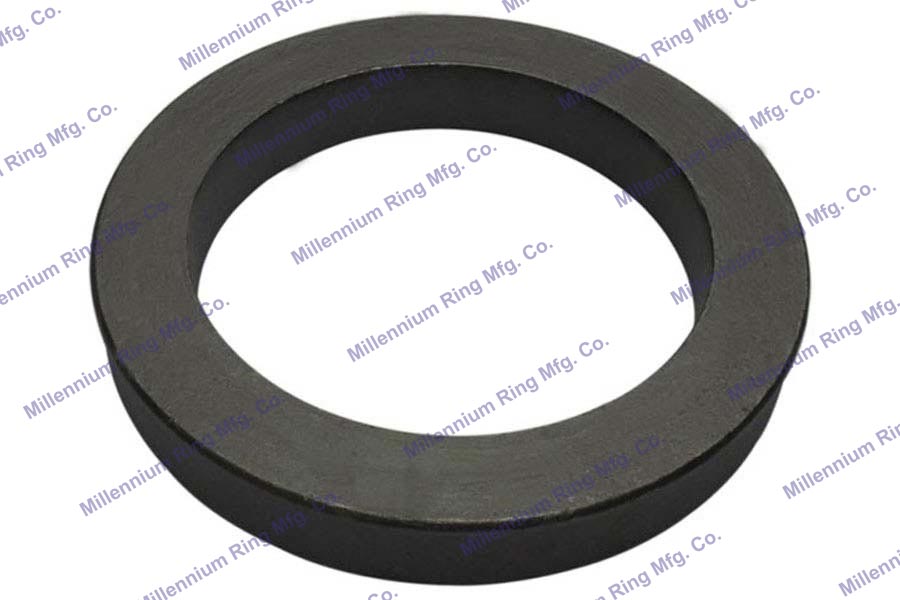

Annulus Ring

Annulus Ring

Annulus Ring is a specific Seamless Rolled Rings intended for a scope of industrial uses. These accurately designed parts are portrayed by their roundabout shape, high strength, and solidness. Annulus rings are utilized to help move hub, spiral, and second loads, causing them fundamental in a mechanical system that requires smooth and proficient rotational movement.

Key Benefits

-

Circular Design

The hollow center is well-suited requiring rotational movement/support around a central axis.

-

Versatile Sizes

Tailored to specific uses, from small mechanical assemblies to large industrial equipment.

-

Material Variability

Includes alloy steel, carbon steel, & stainless steel, depending on the specific needs

-

Precision Machining

Ensures they fit seamlessly within the equipment and facilitate smooth rotational movement.

-

Heat Treatment:

Enhances strength, hardness, and durability, ensuring long-term performance in conditions.

Applications

-

Bearings

Used in the construction of bearings for various industrial equipment and machinery.

-

Wind Turbines

Support and facilitate the rotation of turbine blades to cover wind energy effectively.

-

Machine Tools

For metalworking and manufacturing processes, letting precise & liable functions.

-

Aerospace

In aircraft components, like engine parts, & help withstand extreme conditions.

-

Robotics

Enables the rotational movement of robotic arms, facilitating a huge array of functions.

Annulus Ring is a demonstration of accuracy designing, offering the capacity to help weighty loads, give smooth rotational movement, and guarantee the dependable and proficient activity of hardware across different enterprises. Their seamless development, adaptability in size and materials, and high loads bearing limit make them crucial parts for applications requiring rotational development and load support.

Your Vision, our Precision – Together, Let's Forge Excellence!

Browse Catalog

Housing Ring

Transmission Gear Rings

Hydraulic Ring

Crown Wheel

Gear Ring

Other Ring

Oil Field

Ring Gear

Gear Ring

Slewing Ring

Ring Joint Gasket

Seat Ring

Synchronizer Rings

Ring Gear

Pinions/Hubs

Ring Gear

Ring Gear

Hot Rolled Ring

Cut Blanks