Table of Contents

ToggleIntroduction

Nearly every element of our life is rapidly incorporating artificial intelligence (AI). Its applications are many and ever-evolving, ranging from autonomous cars to geology, medicine, autonomous art, and consumer data analysis.

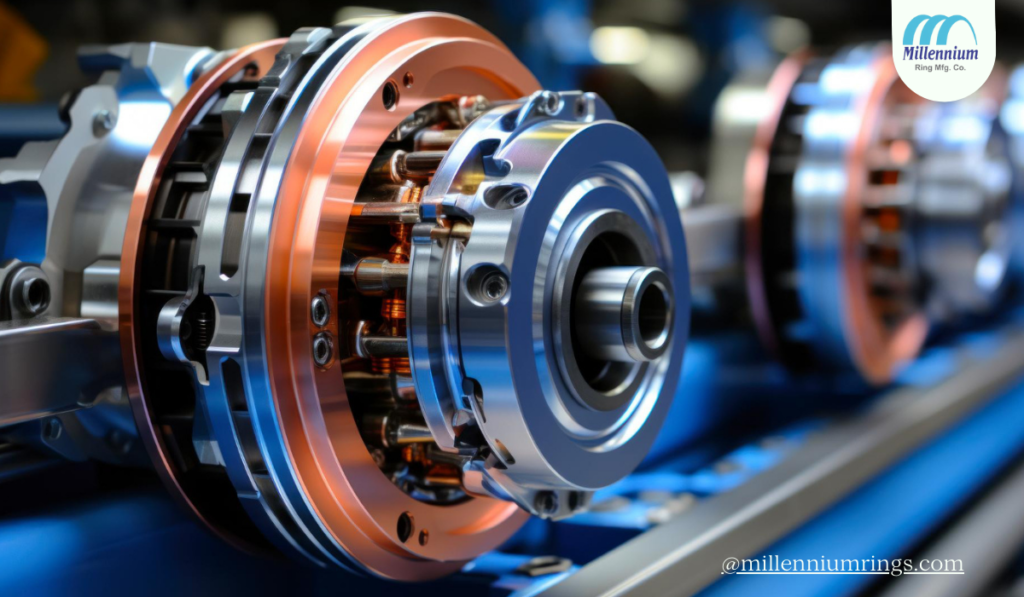

The ring rolling process is commonly employed in the manufacturing of seamless rolled rings for the aerospace and automotive sectors. Recent developments in ring rolling equipment and procedures are highlighted in this technology review.

The use of AI will be a great deal for the rolling forging processes of the rolled rings. Several processes are there to follow. However, the impact of AI and automation in this industry makes everything easy and time-efficient.

Why is AI a Game-Changer in the Field of Rolling Ring Manufacturing?

The advantages of artificial intelligence (AI) for the steel sector are obvious. Any industry with AI can prevent these production-related issues in a number of ways.

AI is far more advanced for better results. It can be helpful by identifying particular design or manufacturing faults that people are unable to notice or understand. The installed system just scans the data to do so. With AI, operators can identify any tiny possible problem.

In certain cases, its right in front of you, but you can’t continuously monitor the data and identify it as soon as it appears.

Therefore, you also require an automated system to identify certain circumstances and alert others to what’s happening. The idea is that you will be able to initiate remedial actions by identifying and monitoring certain events as they occur.

5 Major Roles of AI and Automation in Ring Manufacturing Industries

1. Bring Better Quality Control & Precision

With the use of AI-powered systems, every automation process seems flawless. These are very efficient to analyses and process huge amounts of data at once. It avoids small errors during the rolled ring forging.

There are machines learning algorithms that adapt information from historical data of the ring production. At every stage, the intelligent tool identifies faults and lets the manufacturers adjust accordingly.

While using AI, the manufacturing industry can forge high-quality rolling rings. It also helps to lessen the rate of waste. Additionally, the operator saves more time and cost while the Rolling Forging of the steel rings.

2. Provide Better Maintenance and Avoid Downtime

AI-powered machines can perform flawlessly. That’s why they are capable enough to avoid certain faults from happening. Before the breakdown, the system will remind the operator about the issues.

AI systems can do such wonders by analysing certain information. It gathers data from sensors and machine logs. This proactive approach is a game changer for industries.

With the help of AI, operators can reduce failures, optimize various maintenance periods, save cost, increase efficiency, and raise the lifespan of machinery.

3. Enhance Inventory & Supply Chain Management

AI-powered systems are very good at managing and optimizing inventory levels. It can do wonders with various data from the past. It starts from sales data to economic conditions. Also, it follows the current market trends and other external factors to counter the odds.

With the use of AI and automated machines, manufacturers of rolled rings can handle their excess stock and stockouts. Also, certain improvements in supplier management have made AI a powerful option. It manages the lead times and procurement processes quite easily.

4. Introduce Optimized Production Processes

AI manages the entire manufacturing unit and its various processes. It just does its things by adjusting certain parameters in real time. Various activities such as pressure control, temperature adjustments, and material flows are mostly managed by AI-powered systems.

This is how the entire production unit stays relaxed while handing over the job to AI. However, there is an operator to take care of the entire system.

The system learns from various aspects and improves in further manufacturing or rolled ring forging processes.

5. Bring Forth Innovative Ideas in the Production

The rise of AI is obvious as it introduces the newest and the most efficient production methods. The utilization of such processes helps manufacturers to move on from previous projects and work on the latest. The system learns from the past data and makes the new processes error-free.

What’s New to Bring in Ring Manufacturing with AI?

Machine learning techniques are the source of elevating the elegance of AI in the ring rolling process. It just needs the right methods to process the information. Also, the output will be tested under extreme conditions and outside of the ordinary table.

In this way, the designed software can be tested well enough. If it passes the test, then the pattern of the machine learning will be available to use. If any breakdown happens, it will go for further tests.

FAQs

AI is used in rolled ring manufacturing for process optimization, predictive maintenance, quality control, and supply chain management. AI algorithms analyze vast amounts of data to improve production efficiency, predict equipment failures, ensure product quality, and streamline operations.

Automation in rolled ring manufacturing offers several benefits, including increased production speed, enhanced precision and consistency, reduced labor costs, improved safety, and the ability to run operations 24/7. Automation also allows for more efficient use of resources and minimizes human error.

Predictive maintenance uses AI to analyze data from sensors and other monitoring tools to predict when equipment is likely to fail or require maintenance. This proactive approach helps prevent unexpected breakdowns, reduces downtime, and extends the lifespan of machinery.

Yes, AI can significantly enhance the quality control process by using machine learning algorithms to detect defects and inconsistencies in real-time. AI systems can analyze images and sensor data to identify issues that might be missed by human inspectors, ensuring higher quality products.

Automation streamlines the supply chain by improving inventory management, reducing lead times, and enhancing coordination between different stages of production. Automated systems can track materials and finished products, optimize storage, and ensure timely deliveries, leading to a more efficient supply chain.