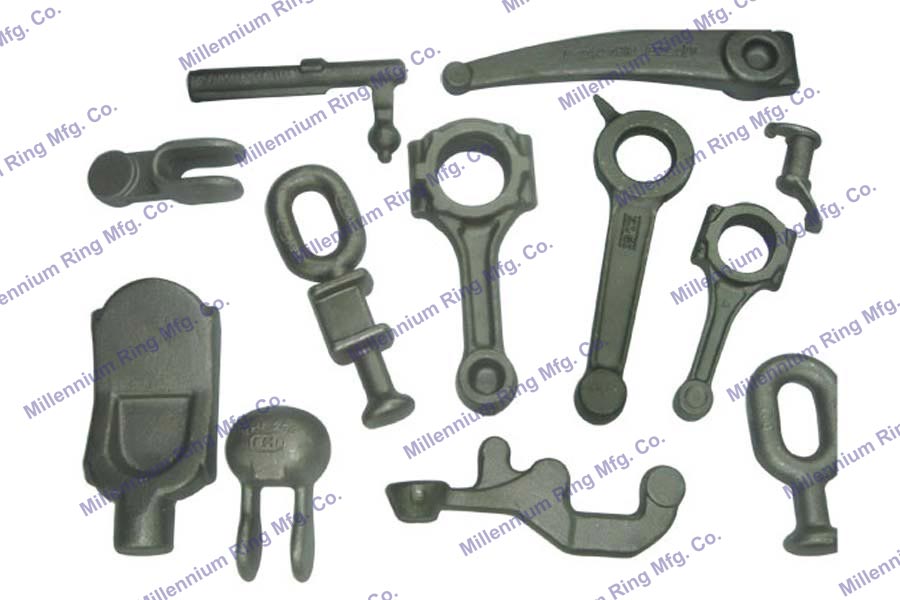

Closed Die Forging

What is Closed Die Forging?

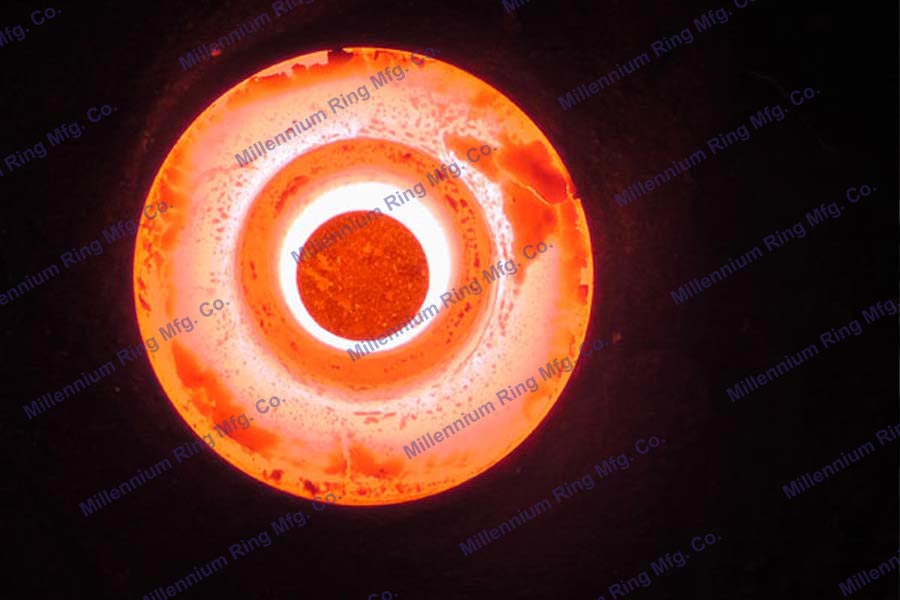

Closed die forging, also known as impression die forging, is a manufacturing process where metal is shaped under high pressure between two dies that contain a pre-designed impression of the final part. This method ensures exceptional strength, accuracy, and consistency, making it ideal for industries requiring durable and high-performance components.

-

Superior Strength & Durability

The controlled forging process enhances the material’s mechanical properties, resulting in components with high tensile strength and resistance to wear.

-

Precision & Consistency

Closed die forging ensures tight tolerances and minimal machining, making it perfect for complex and near-net shape designs.

-

Efficiency & Cost-Effectiveness

With minimal material wastage and high production rates, this method is an economical choice for large-scale manufacturing.

Industries We Serve

- Aerospace – Engine components, landing gear parts

- Automotive – Gears, shafts, connecting rods

- Energy – Turbine components, power transmission parts

- Construction – Heavy-duty hardware, structural components

- Defense – High-strength precision components

Our Closed Die Forging Capabilities

Materials We Work With. We forge a wide range of metals, including:

- Carbon & Alloy Steel

- Stainless Steel

- Aluminum & Titanium

- Nickel & Copper Alloys

Why Millennium Rings?

- Decades of Expertise – Proven track record in forging excellence

- Customized Solutions – Tailored to your specific requirements

- Global Reach – Trusted by industries worldwide

Auto Parts

Automotive Parts

Flanges

Flanges

Gear

General

Housings

Close Die Forging

Close Die Forging

Axle Shaft

Mixed Gear

Textile Alu.Disc

Wind Nut

Cross

Axles

Con.Rod Electronics Tras.

EarthMovers Compressors

Fitting Valve & Body

Track Shoe, Weight Balancer